Baillie Fab Blog

Designing for Maintainability in Sheet Metal Fabrication

Tips and Best Practices for Common Sheet Metal Features

At Baillie Fabricating & Welding, we’ve seen nearly every type of sheet metal fabrication project imaginable. Over our decades of experience, our team has learned what works best and what can drive up costs when you’re adding common sheet metal features to your design.

The (Sometimes Hidden) Benefits of a Full-Service Fabrication Shop

It’s hard to believe, but when Baillie Fabricating and Welding first began more than 30 years ago, owner Stephen Baillie led a one-man operation focused on welding services. Since then, we’ve grown into a full-service fabrication shop by continually expanding our capabilities while maintaining the same quality we’ve always been known for.

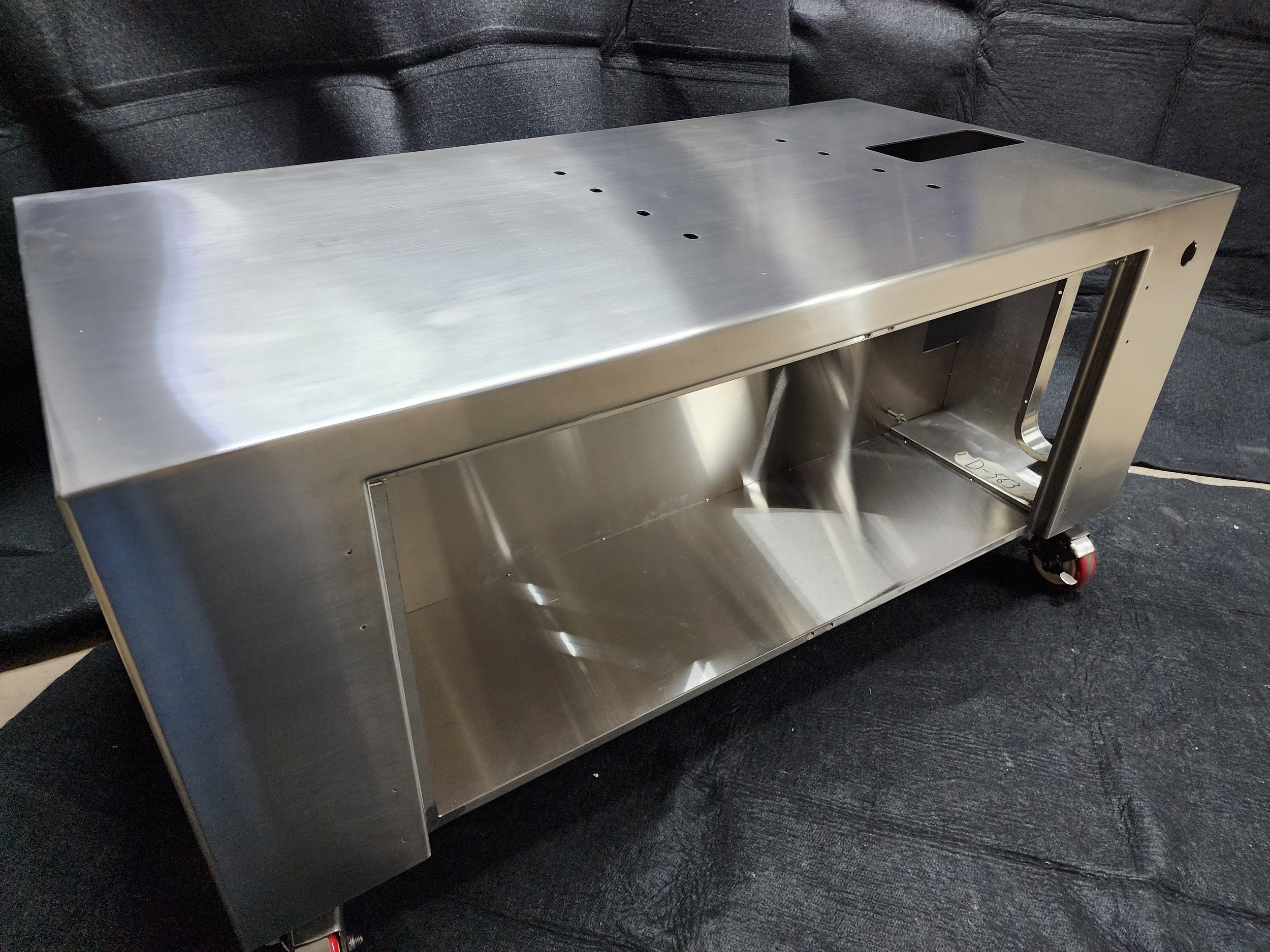

Box Builds: Choosing the Most Efficient Metal Fabrication Method

At Baillie Fabricating & Welding, box builds are a common sheet metal fabrication project we handle for customers. These versatile enclosures are used across a wide range of industries and applications and can be customized to meet specific functional requirements. We often create boxes for pharmaceutical and food packaging partners, where stackability and clean finishes are critical.

6 Ways to Reduce Your Sheet Metal Fabrication Cost

When customers first partner with us for sheet metal fabrication, they’re often surprised by our efforts to help them save money on their project. Some shops simply take drawings and start cutting, but we dive deep into the details of your project to ensure you receive the highest quality parts while still controlling costs.

Avoid the Hidden Costs of Deep Sheet Metal Bends

When you’re designing parts with 90-degree U-shaped bends for sheet metal fabrication, what initially seems straightforward can quickly become costly due to hidden manufacturing complexities. This is especially true for parts with deep sheet metal bends, where the height of the sides is close to or greater than the dimension of the bottom.