The Importance of First Article Inspections in Complex Metal Fabrication

At Baillie Fabricating & Welding, we offer First Article Inspections (FAI) when we begin a new metal fabrication project. In fact, if a part is complex or we will be handling repeat production runs, we often recommend this service to customers even when they don’t initially request it.

Even if a design looks perfect on paper, there’s always a difference between design and reality. It’s like comparing a map to the territory: as the real manufacturing process begins, we may encounter unexpected challenges or identify unclear part requirements, helping to pave the way for smoother, more cost-efficient production.

When We Recommend First Article Inspections

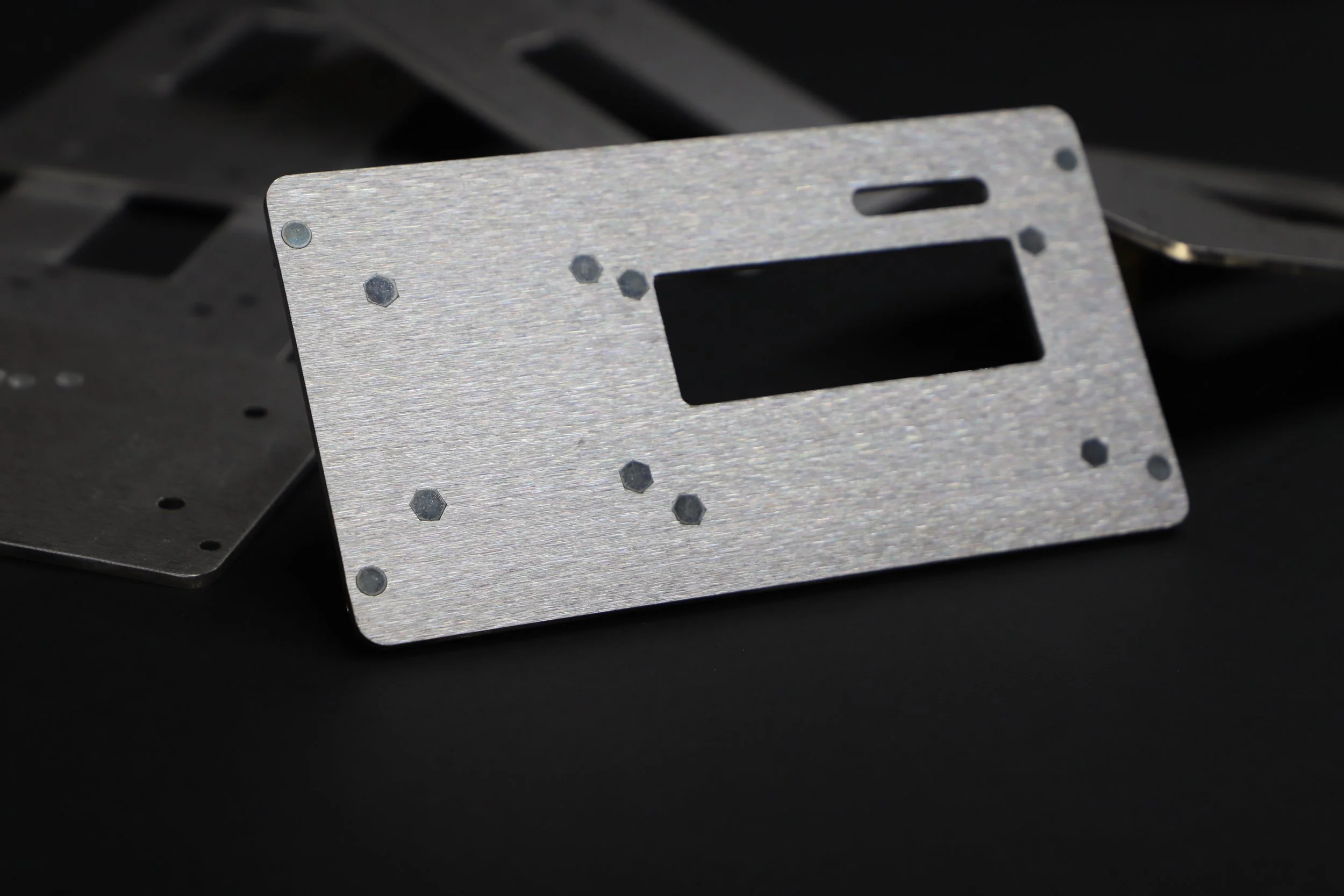

Years ago, a customer came to us with a complex aluminum bracket design featuring numerous holes positioned very close to the bend line. This is against standard design for manufacturing (DFM) recommendations, but they explained that the hole locations were critical to their application and couldn’t be changed.

At that point, we recommended a First Article Inspection so that we could optimize our process, assess our potential scrap rate, and offer them the best possible price for this component.

This is a common use of First Article Inspections in our shop: align with the customer on expectations as we determine how to effectively manufacture complex, repeat parts. In this customer’s case, we were focused on the process. In other situations, we may seek out DFM suggestions to reduce costs or provide a sample part for the customer to test functionality, among other purposes.

Our First Article Inspection Process

We have no one set protocol, but instead adapt our FAI process to each customer and their specific part drawings and needs. We’ll discuss designs with customers and confirm critical dimensions, explaining what deviations from non-critical dimensions may occur before proving it out in our manufacturing process.

Many customers will then take that first physical part and test it in their actual end-use application. They may request modifications or adjustments for either application purposes or DFM cost savings before we move into full-scale production.

The Benefits of First Article Inspections

First Article Inspections help ensure a smoother manufacturing process overall in several different ways:

Improved costs: While FAI may add a small upfront cost, your long-term costs are reduced through decreased scrap, fewer revisions, and more efficient manufacturing.

Greater efficiency: When we can optimize your manufacturing process with that single initial part, we’ll immediately be ready for long-term production success in your next batch.

Alignment on specifications and tolerances: Complex parts often present measurement challenges, and we can align with customers on critical dimensions and proper inspection and measurement techniques.

Testing and modifications: You’ll be able to test your part to ensure it functions as intended before moving into full production.

Let’s Discuss Your Next Part

By performing a First Article Inspection, we can help to ensure your project is a success from the very first step. These First Article Inspections are simply an extension of our commitment to quality in everything we do at Baillie Fab. From CAD modeling services to metal fabrication services to CNC milling, we’re ready to serve you.

Request a quote today to partner with our Pennsylvania metal fabrication shop.